Although crocodile skin itself is a scarce resource, the processes and techniques required for making bags and leather are much more complex and difficult than those of ordinary leather types.

Remove scales and soften

Crocodile skin is not as smooth as other leather types. It has hard scales. To make it into a luxury handbag, the first step is to make it soft. Craftsmen will perform complex chemical steps such as water soaking, alkali soaking, graying, softening, salt washing, pickling and other chemical steps to make the scales loose and fall off, and the leather will swell and become soft. When the hard scales are completely shed, the grain will become clearer and the hand will feel much softer.

Leather selection, cutting, sewing, finishing

The selection of crocodile skin is more demanding than ordinary skin types. The handbags produced by LANA MARKS only use crocodile leather with exactly the same pores, patterns, and thickness. Because of such strict selection standards, a crocodile leather handbag usually requires 3-4 crocodiles to select leather that meets the requirements. Then comes the cutting, hand-drilling of uniformly sized and strictly aligned pinholes, hand-sewing of the cuts, airtight sealing, and then using a specific mold to stretch the bag sewn on the back into the front profile. The leather is then finished using specific ironing tools. It is worth mentioning that due to the special pattern and rich surface particles of crocodile leather, the finishing process is more laborious than that of ordinary leather. Crocodile leather has raised grains and bones inside. After polishing, it needs to be sprayed with chemical agents and polished again to ensure that the crocodile leather has a three-dimensional light feel and a delicate feel.

Tanning

Tanning is to remove all fat, moisture, salt, and impurities from the crocodile skin itself, making it easier to preserve, and allowing the leather to swell appropriately, become moderately hard and soft, and easy to shape. Some crocodile leathers have even been treated with botulinum toxin. Bacillus or chromium, which makes the leather feel lighter, more flexible, and waterproof, just like a woman’s face as delicate as a woman’s face.

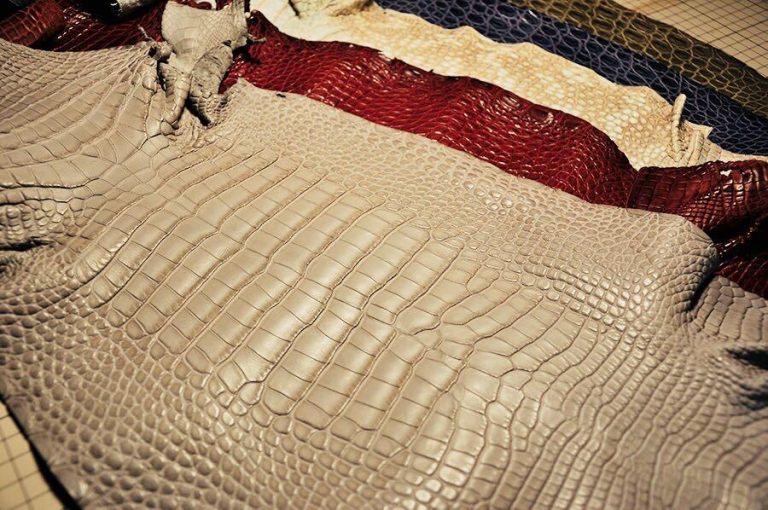

Retanning, fatliquing, dyeing, polishing

After removing the pigmented fat from the crocodile skin itself, the cortex becomes dry and dull. In order to make the thickness and color consistent, craftsmen must open their fiber channels to allow color and wax to penetrate evenly, making the leather deeply colored, firm to the touch, and natural-looking. In this type of process, the production of shiny crocodile skin is different from that of matte crocodile skin, and the latter is more difficult. Small flaws during the sewing process of shiny crocodile leather can be corrected during tanning. Matte crocodile leather is more difficult to process. Once uneven color is found during the dyeing process, it cannot be repaired and the entire leather will be eliminated. Therefore, matte crocodile leather bags are more expensive.